The restaurant industry in the U.S. is one of the most diverse in the country. Based on the Bureau of Labor and Statistics, as of 2011 there were an estimated 10 million people working in restaurants and bars in the U.S.—more than half are women, 11 percent are African American, six percent are Asian, and nearly 25 percent are Hispanic.

The restaurant industry in the U.S. is one of the most diverse in the country. Based on the Bureau of Labor and Statistics, as of 2011 there were an estimated 10 million people working in restaurants and bars in the U.S.—more than half are women, 11 percent are African American, six percent are Asian, and nearly 25 percent are Hispanic.

We can expect all of these numbers to be somewhat larger today. Many of these people work in the back of the house and a large number are involved in the actual cleaning and maintenance of restaurant facilities. However, here’s where we may have a problem.

For many of these workers, English is a second language. In some cases, they may not speak or understand English at all and for others, their reading skills may be limited.

This means, when performing many tasks, including cleaning, these workers may select the wrong product for the task at hand. When it comes to cleaning, this can be very dangerous for the worker, the restaurant, and its patrons. It can also negatively impact the health of the entire property.

Sometimes cleaning workers who are not fluent in English will select a cleaning product based on the shape and look of the container; some base their decisions on familiarity with the label; and, in one case, a female custodial worker would actually open the container and take a whiff. She had an idea what each type of cleaning solution smelled like and selected accordingly, but not always correctly.

None of these are effective ways to select cleaning products; and in fact, they can be very dangerous. They also open the door to lots and lots of mistakes. This is why medical facilities were the first type of facilities to develop a color-coding system. They have been incorporating some type of color-coding system for all types of tasks for decades, such as when washing sheets, using cleaning products, and for medications.

Setting Your Own Standards

Color-coding means placing very noticeable colored labels on a variety of products used for cleaning. But because restaurant owners/managers will likely be creating their own color-coded cleaning system, there are some basics we need to discuss first. For instance:

- Too many colors cause confusion. Red, yellow, green, and blue are the recommended colors.

- Once certain colors have been designated for certain purposes, they should not be changed. Again, this can cause confusion.

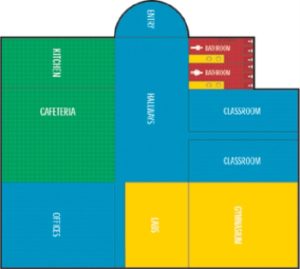

- Each color designates where or how the product is to be used. For instance, red may be for high risk areas, such as restrooms; yellow for mirrors and glass; green for kitchen and food areas; and blue for low risk areas, such as offices in a restaurant.

- Color-coding should extend to the closet where supplies are stored. For instance, because “red” products will typically be used for the same purposes, they should all be stored on the same “red” shelf.

- Color-coding encompasses more than just chemicals. Some cleaning tools are only used in restrooms. The cleaning solutions as well as the tools used in the restrooms should all bear red labels.

- If needed, microfiber cleaning cloths typically are available in specific colors. These cloths should follow the same color-coding room and product designations.

- If gloves or any other type of protective clothing are required for certain cleaning tasks, they should also match room and product color-coding. For instance, if red products are used to clean the restrooms, red-labeled gloves are to be worn and green labels would be on gloves worn in food preparation areas.

Tying it All Together

View color-coding as a communication system for the entire restaurant. Through the use of colors, we are both educating and communicating to all workers—even those that may not be involved with cleaning—which products are to be used where on the property. And there is one more thing that should be color-coded. This year, Material Safety Data Sheets (MSDSs), are being phased out and replaced with the global Safety Data Sheet (SDS). In an emergency, we certainly do not want workers scrambling to find the right SDS for a red-colored cleaning product. Color-code this safety information as well with the primary goal of clearly organizing and cataloguing specific cleaning products with their specified SDS.

- While our goal is to promote safety and ensure the right cleaning products are used in designated areas, some restaurant owners/managers may take this a step further. Because the food preparation area is typically the most soiled part of the restaurant, some color-coding systems are developed just for these areas. For instance, a gray color—for products and cleaning solutions—may be used for cleaning stainless steel surfaces; another color for wood cutting boards; and another color for chemicals and products used for less regular cleaning of such areas as vents, walls, and other surfaces.

- When first creating a color-coding system, it’s a good idea to take the time and draw a floor plan of your entire restaurant. Designate certain areas where “yellow” color-coded products, for instance, are to be used; where red products are to be used; etc.

Ron Segura is president of Segura Associates. His company works with large organizations to streamline their cleaning and building operations as well as promote sustainability and healthier cleaning strategies so that facilities function more effectively and efficiently and realize a cost savings. He can be reached through his company website at https://www.seguraassociates.com.